6 Reasons for customised drives

We optimise drives for dynamics, speed and precision. So you can design machines for maximum productivity.

The advantages of electrical over hydraulic drives in injection moulders and extruders are commonly known: superior efficiency, ease of configuration, quieter, higher precision, faster and parallel movements, easier to maintain and suitable for clean rooms.

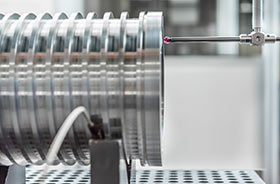

We build electric motors in our high-tech Manufacture that are developed for your requirements, to give you maximum benefit from drive technology.

- High dynamic response – your injection unit achieves maximum speed thanks to drives with minimal inertia and high maximum torque

- Complete system integration – maximum interfacing flexibility, e.g. with specific bearing and flange designs and electrical connector arrangements; total compatibility with all inverters and sensor systems.

- Flexible design – extra-compact heights or lengths are possible for greater dimensional freedom in the design of your machine

- Highly efficient – lower current requirement and correspondingly lower-cost inverter, as the motor is designed precisely for the required rotational speed

- Thermally optimised – minimal heating of the rotor and surface thanks to water cooling

- Available quickly – initial prototype ready within weeks for your testing